FRP grating

Applicable field

Specific purpose

Performance characteristics

1. Corrosion resistance

Different performance resins endow the grille with different corrosion resistance, which is suitable for the corrosive environment of gas and liquid media with different acids, alkalis, salts, and organic solvents.

2. Flame retardant

The high-quality matrix resin and flame-retardant additives give the product excellent flame-retardant performance. Generally, the oxygen index of the flame-retardant grille is greater than 26, the flame diffusion coefficient is less than 25, the smoke density is less than 500, and the oxygen index of the product with special formula design can be greater than 35. The grid oxygen index is greater than 50, and the product has passed the American Society for Testing and Materials (ASTM) flame retardant test.

3. Lightweight and high strength

The perfect structure of the alkali-free glass fiber yarn and the resin interlaced weaving gives the grille unique light-weight and high-strength characteristics. When used for other functions, its weight is only 1/4 of steel, and its strength exceeds that of steel. Various sizes make it Suitable for all kinds of load-bearing occasions.

4. Anti-aging

The product is made of high-quality glass fiber and resin, plus anti-aging additives, which endows the grill with long-lasting anti-aging performance. The unique inner grid design makes the grill have a good self-cleaning function, so that it can maintain a long-term luster and continuous High strength, service life of more than 50 years, foreign experts even assert that the use of special means can make the life of more than 100 years.

5. Safe anti-skid

High elastic modulus and different surfaces make the grille have anti-skid performance, slight elasticity reduces the fatigue of the staff, bi-plane, crescent surface, sand surface, diamond cover, different surfaces provide anti-skid performance for different use occasions.

6. Designability

The characteristics of the composite material endow the grid with flexible design performance. In addition to the above characteristics, the color of the product is based on the standard colors of yellow, green, blue, gray, orange, and black provided by the company, and can be provided according to customer requirements Color and product dimensions are based on the standard size provided by the company, and can be cut or spliced into any size required by customers. In addition, the special requirements of the grille in special occasions can also be designed to achieve the best function.

7. Electrical performance

Alkali-free glass fiber and high-performance resin endow the product with superior electrical properties, the product's breakdown strength can reach 10KV/mm, and there is no spark when metal tools are impacted; the product is non-magnetic and can be used safely in anti-magnetic and anti-explosive environments.

8. Economy

The initial investment of FRP grating is larger than that of steel grating, but it does not require maintenance costs and has a long life. Therefore, the overall economic benefits are better. According to calculations, the price ratio of FRP grating to steel grating is 1 : 2.2.

Product specifications

Standard grid reference number table

Selection guide

1. Type selection

The selection of the grid type mainly considers the load-bearing form, the maximum working load and the span of the supporting structure when in use, as well as other requirements such as corrosive media and ambient temperature. The normal load-bearing forms include center point load, center line load, and uniform load. There are three types of installation: firm installation, standard installation and flexible installation. Use firm installation when the working environment is harsh, long-term heavy load or high-rise use; use standard installation under normal circumstances; short-term load, that is, generally use flexible installation when the load is small and the platform is low. The maximum deflection rate of the grille does not exceed 1%. According to the specific use environment and installation requirements, refer to the standard size table to determine the placement and load span design of the grille. The customer selects the most suitable grille type. (See Table 3)

2. Resin selection

The corrosion resistance of the grid mainly depends on the matrix resin of the grid. The company has established good cooperative relations with internationally renowned chemical companies such as Ashland and Dsm, and is exclusively authorized by Ashland to use the Ashland logo. According to the specific corrosive environment and media conditions used by the grid, refer to the grid corrosion resistance guide to determine the most economical resin type. (See Table 2, 7)

3. colour

The choice of grid color mainly depends on the coordination between the product and the surrounding environment and the aesthetic habits of customers. The company can provide six standard colors of yellow, green, blue, gray, orange, and black and transparent grids for customers to choose. According to the samples, color plates or designated color cards provided by customers.

4. surface

The surface form of the grille mainly depends on the non-slip requirements of the use occasion. The company can provide six different surfaces of crescent surface, sand surface, double plane, diamond plate cover, sand panel cover and flat panel cover for customers to choose from, but the cover type The grille increases the thickness and weight of the grille. And will greatly increase the strength of the grille.

5. Flame retardant requirements

The flame retardant performance of the grille mainly depends on the flame retardant requirements of the use occasion. The normal flame retardant grille of our company can be used for general flame retardant occasions, and the phenolic grille can be used for high flame retardant requirements. The transparent grille is non-flame retardant. Grille.

6. special requirements

The company has strong grid product development capabilities and mold development and manufacturing capabilities. If customers have special requirements for grid load, corrosion resistance, conductivity, anti-static, etc., our company can provide special design and production.

The company's grille is installed quickly and has complete accessories. It can be installed and laid according to customer requirements, and cut and processed for customers, and can be installed on site or provide installation guidance services for customers to achieve the best economic results.

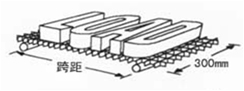

Platform installation:

1. The supporting edge of the grid shall be supported by at least 40mm wide on the steel beam, the installation gap between the grid and the grid is 6mm, and the installation gap between the grid and the concrete column is 10mm.

2. The grid and the supporting steel beam should be fixed with M-shaped or L-shaped clamps. Each grid should be at least 4 pieces. The edges of two adjacent non-supporting grids should be connected by C-shaped clamps. Use at least one m-length center.

Trench installation:

1. Refer to the grid size and adjust the trench size as much as possible, so that the edge of the grid is closed after cutting, to maintain the integrity of the cell, and achieve a beautiful and generous installation effect.

2. The grating has at least 40mm wide support on the concrete foundation, and the gap between the grating and the concrete is 3-6mm.

Stair installation:

1. The grille step should be installed in the step frame, the frame can be four ordinary steel frame, it can also be a glass steel frame.

2. The gap between the grille step and the frame is 3-6mm, each step is fixed with 8 fixed clamps, and each corner uses two.

3. The grid fixing fixture provided by our company is divided into M type, L type and C type. Different clamps have different functions: M type is used for positioning and connection between the grid and supporting structure; L type is used for the grid and The supporting structure is connected with a special limit; the C type is used for the integral connection between the sides of the two grids. The company also supports corresponding screws, gaskets and other accessories.

Grille maintenance:

1. In the course of use, detergent can be used to clean the surface dust and dirt, without other maintenance measures.

2. During use, direct contact with various open flames and high temperatures such as electric welding, oxyacetylene flame, etc., should be avoided during the maintenance of steel structures and equipment.

During use, avoid dragging, bruising and paint contamination of various steel materials, steel sharp tools, tools, etc. during maintenance of steel structures and equipment.

Resin type Table 2 table 2

table 3

Molded grille-load bearing performance

Moulded grid uniform distribution load table-deformation (mm)

Scan the QR code to read on your phone

Copyright: Nantong Jinhai Anti-Corrosion Co., Ltd. 苏ICP备06060963号 Powered by www.300.cn